The gold recovered from mining is not pure. The process of refining gold is used to remove the numerous impurities that are mixed in with it. To convert raw gold into high-purity gold, the gold refining process entails numerous processes.

- Finding gold is the initial step in the refinement of gold. Geologists search for potential locations for gold resources using specialized maps to accomplish this. Once they identify a potential gold deposit, geologists use geochemistry, geophysics, and remote sensing to conduct tests to determine whether their suspicions were accurate and whether gold is there. The geologists’ next task is to conduct a drilling operation to collect rock samples. After that, these samples must be examined. The mining engineers must choose the type of mine that will be most appropriate for the region based on factors like the quality of the gold. There is a lot of preparation required, such as the construction of processing plants and roadways. After all that, mine got ready for operation.

- Sampling and preparation: The gold remains in its unprocessed state even after it has been removed from the earth. Sample the substance and analyze it to establish its composition and impurities, including how much gold is there, using a fire assay or instrumental methods like atomic absorption spectroscopy or X-ray fluorescence.

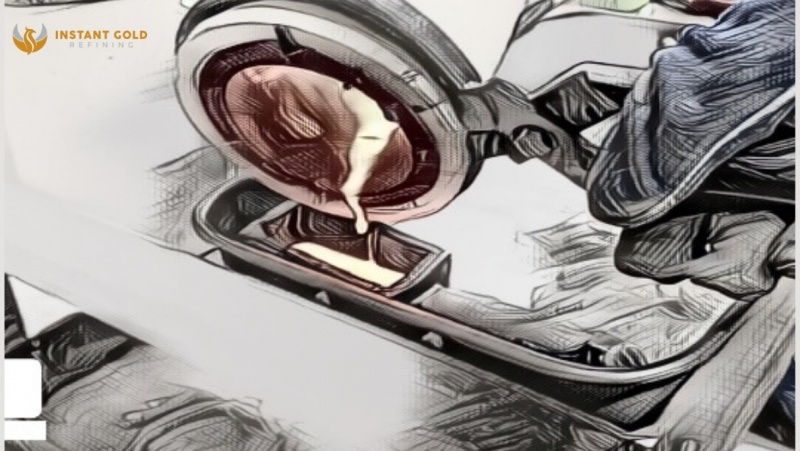

- Melting: The gold material is melted after it has been prepared to make it more workable for subsequent processing. Normally, high temperatures are used to melt the material in a furnace or crucible. This process makes separation and purification easier.

- Chemical Treatment: To get rid of impurities, the gold after it has melted is put through chemical processes. There are several different chemical procedures that can be used, such as acid treatment, precipitation, or chlorination.

- Filtration and Purification: the gold solution is purified by removing undissolved impurities and solid residues. Vacuum filtration, gravity filtration, and other specialized methods of filtering are all possible.

- Precipitation and Smelting: The gold is precipitated out as a solid using procedures known as precipitation, such as adding chemicals to the solution. The resulting “gold mud,” as it is commonly known, is then gathered, and smelted to create a gold doré bar.

- Refining and electrolysis: To produce high-purity gold, at this point, electrolysis, using a pure gold cathode as an electrolytic cell’s anode and a gold doré bar as the bar’s anode, is a common technique. The traditional process used in gold refining is a fire-assay method called cupellation, in which gold, and silver are separated from base metals and other impurities. However, contemporary refineries may make use of alternate or cutting-edge methods, such as electrolytic refining.

- Final Assay and Quality Control: To precisely determine the gold content, this test is often carried out using fire assay or instrumental analysis methods. To make sure the gold reaches the specified specifications and conforms with legal requirements, quality control checks are carried out.